|

http://www.ozvalveamps.org/ava100/ava101moody-aggh.html | Created: 10/01/11 | Last update:

2021/05/18

<<< OzValveAmps |

AGGH member “Moody” built a Lamington but for various reasons wasn't totally happy and thought he could do better with a second shot at it. These are the pix he posted of his rebuild.

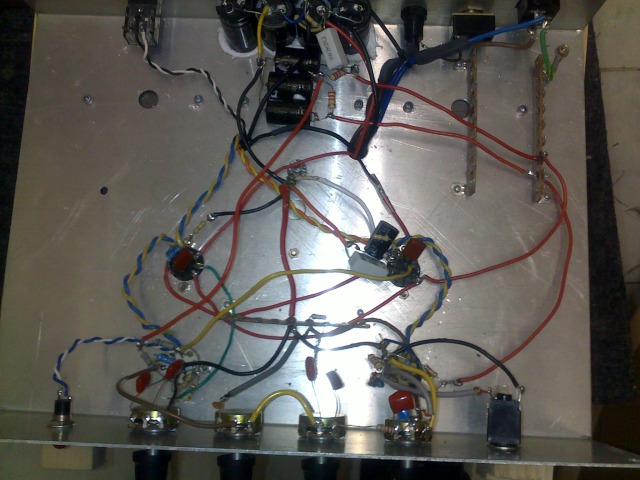

A sheet of aluminium and a bit of folding later produced a U-chassis which is a bit bigger all 'round than the Lamington tray, and has vertical sides for the front and back panels.

Note the central single star earthing point

The job's not done until the mains infeed is sleeved!

There are a a lot of aeroboard or flying connections where components are only supported at one end. This can be fine for lighter components like resistors, but heavier components like capacitors really need to be held down both ends if they are to survive road travel.

It was normal in era builds to mount tagstrips on the same bolts as the valveholders. If you use long tagstrips you can mount two bridging between pairs of preamp sockets and get lots of local tie points.

I'm cheap, so I use strips of Vero™ or strip-board, cut across the strips about 5 holes wide, and bolted copper side up between sockets to provide local tie and support points. Even the edge connectors sawn off old computer cards can be pressed into this service.

Now that hookup wire is free (dead computer power supplies) consistant colour-coding will help you when you come to service your own creation.

|

|